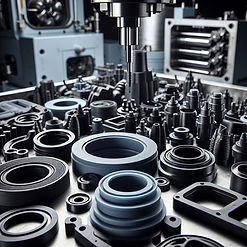

Custom Part Manufacturing

Work directly with our sales / engineering team for pricing and next steps

Our Proven Process

In order to provide a custom quote and make samples, we'll need the following information to get started:

1. Part Specifications

We generally receive a customer print with the following information:

-

Dimensions (w/ tolerances)

-

Material Requirements (e.g. 1020 steel)

-

Let us know if alternate materials are allowed

-

-

Finish Material Requirements (e.g. Zinc plating)

-

Our engineering team can create a print if you only have an existing part available

-

You must own the rights to manufacture the part

-

We can also help modify an existing print (ask our sales engineers to learn more)

-

Our engineers can help with design review and design improvements

-

2. EAU

This stands for Estimated Annual Usage. The quantity helps determine price, the larger the quantity, generally the better price we can achieve through economies of scale. We also use this to determine how much inventory we keep in our warehouse for you to pull from on demand.

3. Package Requirements

Would you like the package quantity to be separated into monthly, quarterly, bi-annual or annual quantities? Even though we package them in specific quantities, our customers are welcome to order any packaged quantity on-demand, per their production requirement needs.

Some customers prefer specific wrapping / cardboard that they are already accustomed to with their current supplier, and we should be able to accommodate most packaging requests.

4. Number of Samples

While we work with our suppliers, we need to know how many samples you require for quality testing by your team. Samples can generally be made within 4 - 6 weeks to expedite the decision process.

Once we have the four pieces of information above, WMC works with our suppliers to get you the best price back within 10 business days. The quoted price will include inspections, shipment, customs (tariffs), and warehousing at no additional cost to you. Our customers simply pay for the freight charges from our warehouse to your receiving department. This is why we have become the preferred supplier for our customers. We handle everything, allowing you to focus on your customers and your production line.

After we agree on a quoted price, WMC will move forward with producing samples. Our sales engineer will explain the next steps involved and our proven process to move your approved samples into production. We are committed to an excellent customer experience, so feel free to ask questions and share your feedback. Our team is here to assist you every step of the way, ensuring your needs are met promptly and effectively.

We work directly with you, so please reach out to our sales team by using the "Contact Us" button below to begin the discussion of your project requirements, get a quote, or learn more about how we can best support your manufacturing needs. We’re here to help you every step of the way.

Available Processes

Metal

-

Sheet Metal Fabrication

-

Laser Cutting

-

Stamping (Slow / Fast)

-

Tube Bending

-

Wire Forming (e.g. Chain)

-

CNC Milling/Turning

-

Metal Injection Molding

-

Casting

-

Aluminum Extrusion

-

Forging

Plastic

-

Injection Molding

-

Extrusion

-

Compression Molding

-

Blow Molding

-

Thermoforming

Rubber

-

Injection Molding

-

Extrusion

-

Compression Molding

This is a general overview. We would be pleased to review your specific design and provide you with a competitive quote.